GLAZING

Confident Home Remodelers is right at the cutting edge of change in the cellar door industry. We are the glazing specialists. We don’t paint these cellar doors, we glaze them. Would you want your bathtub painted instead of glazed? No, of course not. You’d laugh at any contractor or supplier that offered a bathtub painted. A bathtub is steel, it’s constantly wet, and therefore the only acceptable coating is glazing. You already know that, it’s public knowledge.

Hmmm, that sounds a lot like a cellar door. Cellar doors are steel, and they are constantly wet….so, why don’t we glaze them? You’d think someone else would have thought of this already. Evidently not. That’s just who I am. My business is surging with orders for glazed cellar doors. The idea was immediately successful. I otherwise don’t follow the herd on anything.

Our glazing is not a traditional two-part epoxy mix either. It’s a three-part mix, with an optional fourth component depending on how it’s applied. Hey, we’re in New Jersey, and this is the leading State for all things chemical. If the change to glazing is going to happen to the cellar door industry, it makes sense that it would happen in New Jersey. And it did. We took the bold step forwards in April, 2023, and we’ve already installed dozens of glazed doors.

There are a couple of reasons why we’ve decided to make the big transition.

1. Customers with Bilco’s powder-coated units complain that rust is coming through. Every powder-coated unit will be showing some rust within 6-12 months. The PICTURE ON THE RIGHT was taken in April, 2024. It's the front piece of a Bilco Powder-Coated White unit installed in May, 2021. We cannot accept that the manufacturer's powder-coated finish fails so badly so quickly.

2. We first tried Rustoleum products, and they rusted through as well. Rustoleum paint also has a very long cure time, and the finished product more easily scratches. High-end paints by Benjamin Moore and Sherwin-Williams were just a tad better. Apparently, there is no paint solution that stops the rusting; water enters on a microscopic level and reaches the steel. Glazing is a superior finish because it is non-porous. It’s thin like paint, but it is NON-POROUS. Water does not reach the steel. The glazing also cleans far quicker and easier.

There’s an amazing story as to how we got into the glazing business. In March, 2022, I met a customer living in a Multi-million-dollar mansion in one of the most exclusive towns in New Jersey. He is also a contractor, but all he does is thick glass shower doors. He’s constantly turning down full bathroom jobs, and all other business. I was intrigued that he's so successful with such a narrow scope of services. He advised “Pick one service that you do really well, and that earns you great money, and then specialize in that field and become the leading expert.” I realized he was right. I decided to specialize in cellar doors, and to focus all our effort and energy in that direction to become the best of all installers. By the Fall of 2022, over 60% of my business was cellar doors.

Then a year later, in March, 2023, another customer contacted me to rebuild some basement stairs. Turns out that he manufactures and supplies industrial glazing. Seriously now, what’s the chance of me meeting a glazing supplier? God must be on my side, to bring us together. A week later I arrived at his factory with a few cut pieces of spare Bilco parts. He glazed them, and then let them sit in water for a week prior to testing them using various scientific tools.

“Hmmm, I might need glazing for my steel Bilco doors”, I said. His eyes perked with interest. Yes, I rebuilt the basement stairs, and I did an astounding job. A week later I arrived at his factory with a few cut pieces of spare Bilco parts. He glazed them, and then let them sit in water for a week prior to testing them using various scientific tools.

1. ADHERENCE : One test was called “adherence”. Using some complicated tool with tiny diamond bits, he scratched the sample in a crisscross pattern. He reported that adherence is 100%. This far outperforms any paint. If properly installed, the glazing will never peel or flake off. It can’t be chemically stripped either. If you really want to remove the glazing, you’d have to sand it off with a rotary sander. I’m telling customers to be sure they want the glaze for the Bilco, because once it’s glazed, that’s it, it’s glazed forever. Theoretically a glazed Bilco can be painted, but why do that?

2. NON-POUROUS : The glazing is non-porous, meaning on the microscopic level, water does not penetrate through to the steel. This means that the steel will never rust. It’s encapsulated, and water cannot reach it. The product is a bit like the original glazing on a bathtub. Unless someone is scrubbing a bathtub with steel wool and industrial cleaning chemicals to remove soap scum or lime, the glazing on a bathtub never fails. Probably it’s a good idea to refrain from scrubbing a cellar door in that fashion.

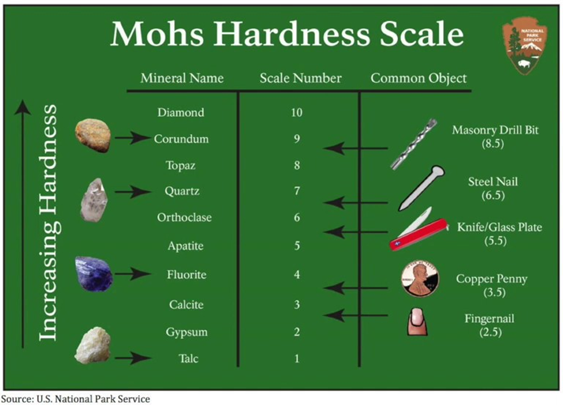

Common substances and their Moh’s Hardness Ratings

- 1 Talc

- 1 Vinyl composite tile

- 1 – 1.3 wood

- 1.5 Ice

- 1.5 Plastic

- 1.5 to 2 Gypsum

- 1.8 Calcium

- 2 #2 Pencil

- 2 to 2.5 fingernail

- 2 to 2.5 Halite (rock salt)

- 2.5 Galena (lead ore)

- 2.5 - 3.0 Gold and Silver

- 2.75 Aluminum

- 3 Calcite / Coral

- 3 Automotive paint (that is the hardest paint out there)

- 3.5 Copper penny

- 3.5 – 4 Dolomite

- 4 Fluorite

- 4 Iron, Nickel

- 4 Limestone, sandstone, marble

- 4.5 = Industrial Glazing

- 5 Obsidian / Volcanic Glass

- 5 – 5.5 Glass

- 5 Concrete

- 5.5 Knife

- 6 Granite

- 6.5 Steel nail

- 7 Porcelain

- 7 Quartz

- 8 Cubic Zirconia

- 8.5 Masonry Drill bit

- 9 Ruby

- 10 Diamond

3. MOH’S HARDNESS: Minerals and other substances can be rated using the Mohs Hardness Scale. Many people have heard that a diamond is the hardest substance, nothing can scratch it, and that it rates a 10 on this hardness scale. Our industrial glazing rates a 4.5, which is far stronger than any paint. It’s in between iron and steel, and rates harder than coral, calcite, silver, gold, copper, dolomite, limestone, sandstone, and marble. Rustoleum paint is so soft that a #2 pencil will scratch it. Here’s two sources listing some common substances, and their ratings on the hardness scale https://geology.com/minerals/mohs-hardness-scale.shtml and https://simplicable.com/materials/mohs-scale

4. RUST TEST: He had a large steel object with his industrial glazing sitting outside his factory for 2 years. I saw it. It’s not rusting. Our glazing is going to be a miracle solution for Bilco’s in coastal areas. Bilco’s at The Shore rust out very quickly due to salt in the ocean air. Glazing is not going to help any steel object that’s already rusted, but "once you glaze over the manufacturer's red primer, it should never rust." That’s straight from the mouth of the glazing supplier. So far, so good. The only outliner is that where the steel double-L latch rubs against the steel of the doors, it will scratch from normal use, and there may develop a slight rusty discoloration at that spot. To avoid this, the manufacturer would theoretically have to use a non-steel part.

Here’s the old wood unit in Ridgewood.

Very sad, very leaky, and a security hazard.

The first glazed unit was installed in Ridgewood, New Jersey. He chose a dark grey for the glazing color. We did the glazing at our shop two days before the install. It’s important to glaze before the install, and hit every square inch, so there are no untreated surfaces. The history of the cellar door industry is that they rust from the inside (from condensation) faster than from the outside that gets rain and snow. Both painted and unpainted surfaces embedded in cement will rust out the fastest. This would be the front bottom piece, the bottom flange of the triangular side panels, and especially any triangular side panel fully touching a masonry stairs or landing.

On the first install, I had to scrape some partially hardened concrete off the bottom of the glazed Bilco unit with a steel chisel. The chisel took it off without scratching the glazing. I simply couldn’t believe it.

The demolition uncovered multiple problems. It was much worse than either myself or the customer envisioned.

Here’s a close-up of the foundation. Many rocks were loose, and had to be reset with the special cement we use.

Here’s the glazed unit, installed onto the new foundation. We had to come back a second day, just for a few hours, to do the final carpentry, above and around the Bilco.

Sherwin Williams Colors

The Glazing Supplier uses dyes from Sherwin Williams (SW) to give color to the main base resin. The other additives and the "Activator" are all clear. The link to their online color selection is here:

Our glazing supplier can exact-match any color from SW6000 to SW7750. They will mix colors out of that range "by eye", but will not guarantee an exact match. In these instances, our contract terms will be that the customer accepts color as mixed, whether it is exact match or not.

There are hundreds of potential colors to choose from, but the majority of customers choose grays and dark Earth tones in the tan to light brown range. Some customers want an exact match to the vinyl siding, while others want a match to the foundation or to other colors in the immediate vicinity. Still others want an offsetting color, a bit lighter or darker than their siding or foundation, but in the same color family. For example, we can glaze a dark red that looks great next to bricks. It's your house, and you can choose the color, even if you want White. We discourage White and other very light colors, because leaves, pollen, and rain hitting the soil nearby will make it look dirty.

30% - 40% of customers choose the exact same dark grey color. We call it "standard dark gray", and it is an exact match for the most common dark grey in Trex decking. And the Trex dark grey is an exact match to the most common dark grey used in patio furniture.

Standard Dark Grey matches common decking color

Other Applications

The glazing can be used for a lot more than cellar doors. I have a strong feeling that aluminum and steel objects, once glazed, will forever withstand the salt air corrosion problem in coastal areas. The boating industry would be well-served with this glazing. We’ve started experimenting with touching up rusted objects around jobsites. I glazed a standpipe in Basking Ridge, the track of a security door in Paterson, and a table in North Arlington. We’ll see how glazing over light rust holds up over time, or if some primer is needed.

The reason that “Standard Dark Grey is the most popular glazing color for cellar doors is that it is extremely close to being an exact match for the most popular color of outside patio table sets (before the table set paint fades). Below are before-and-after pictures of a patio table that I glazed. I scraped and sanded the rust, and glazed in Standard Dark Grey. "

GLAZED CELLAR DOORS is the leading installer of cellar / bulkhead doors in Northern New Jersey and the Lehigh Valley area of Pennsylvania. We install Bilco, Steelway, and Gordon.